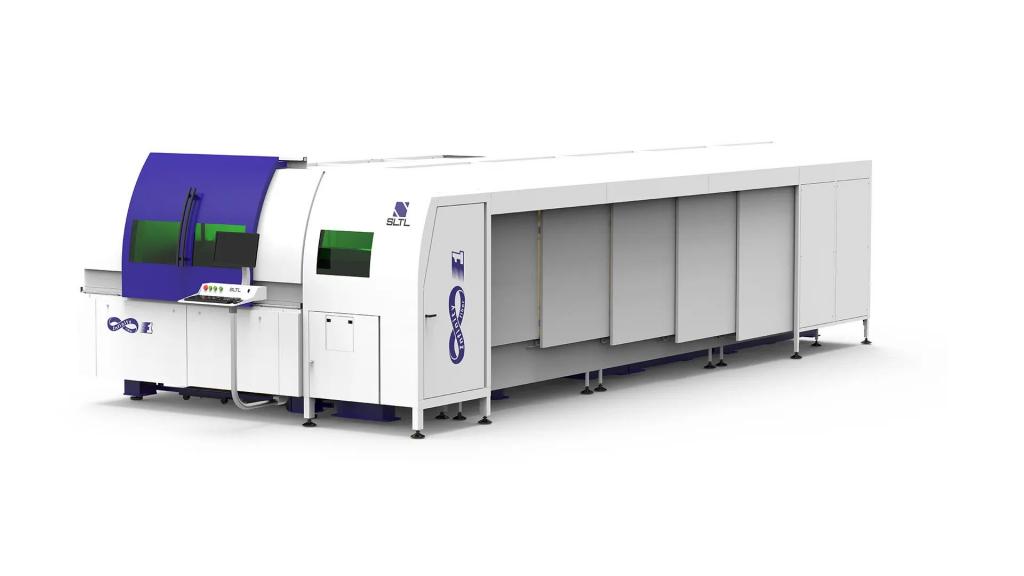

That's great to know that SLTL Group offers a range of sheet metal laser cutting machines in the United Kingdom. The features you mentioned for their laser cutting machines are quite impressive:

- Power Range: SLTL Group offers laser cutting machines with power outputs ranging from 1.5 kW to 10 kW. This range allows for cutting various thicknesses of sheet metal efficiently.

- Fume Suction: The inclusion of a fume suction system helps in removing the smoke and fumes generated during the laser cutting process, ensuring a cleaner and safer working environment.

- Class 1 Enclosure: A Class 1 enclosure refers to a fully enclosed laser cutting system that provides operator safety by preventing direct exposure to the laser beam.

- Pallet Changer: The presence of a pallet changer enables automatic material loading and unloading, allowing for continuous and efficient production without the need for manual intervention.

- Tube Cutting Mechanism: SLTL Group's laser cutting machines also come equipped with a tube cutting mechanism, enabling precise and accurate cutting of tubes and cylindrical objects.

- Filtered Fume Extractor: The filtered fume extractor helps in further purifying the extracted fumes before releasing them into the environment, contributing to a cleaner and healthier workplace.

- Auto Focus Cutting Head: The auto focus cutting head feature allows for automatic adjustment of the focal length, ensuring precise and consistent cutting results across different material thicknesses.

- Light Curtain: The light curtain is a safety feature that uses infrared beams to create an invisible barrier, detecting any intrusion into the cutting area and immediately stopping the laser cutting process, thus preventing accidents.

These features collectively make SLTL Group's laser cutting machines suitable for various sheet metal cutting applications while ensuring operator safety, efficiency, and high-quality output.